When entering the Iranian market, the vanity cabinets created a revolution in bathroom decoration. The modern and different design of these wardrobes not only adds more beauty and order to the space but also provides a suitable space for storing items such as towels, napkins, and detergents. These features have made the vanity cabinet one of the most popular choices in the market. In this article, we will examine the steps of making a PVC vanity cabinet. From the initial design and planning to the final packaging, each step requires special care and attention.

The steps of making a PVC vanity cabinet

1- Designing a vanity cabinet

Needs assessment and spatial survey:

First, the customer's needs and the available space are checked. This includes measuring the space accurately, checking the location of the sewer pipes, and determining the number and type of items to be stored in the vanity cabinet. This information helps the designer to provide a suitable and practical design.

Preparation of the initial plan:

Using the design software, the basic design of the vanity cabinet has been prepared. This plan should include exact dimensions, the location of shelves, doors, and other details. You should also pay attention to the overall style of bathroom decoration so that the vanity cabinet is in harmony with other components.

2- Selection of raw materials

Foamed PVC sheets

Due to their high resistance to moisture and anti-scratch properties, these sheets are an ideal choice for making vanity cabinets. Also, these sheets are not easily stained and are resistant to mold and insects.

connections

Choosing the right handle, hinge and other parts is also very important. These parts must be of high quality and resistant to moisture.

3- Cutting the foam sheet

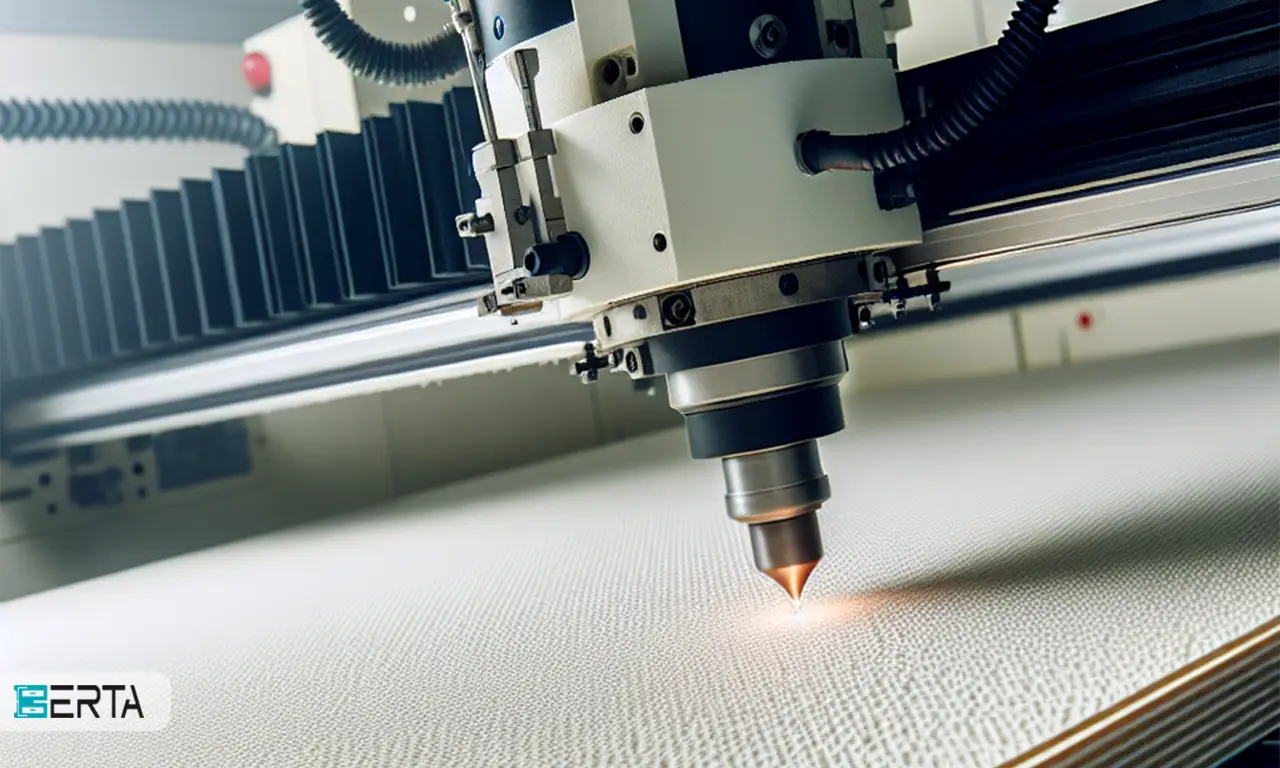

Precise cutting

Foam sheets are converted into the required parts using cutting machines. Accuracy is very important at this stage so that the pieces fit together well. For this purpose, CNC or laser cutting machines are used, which have high accuracy.

edging

The edges of the cut parts are smoothed and polished so that the appearance of the cabinet is beautiful and professional. This is done by using edges that smooth the sharp and uneven edges.

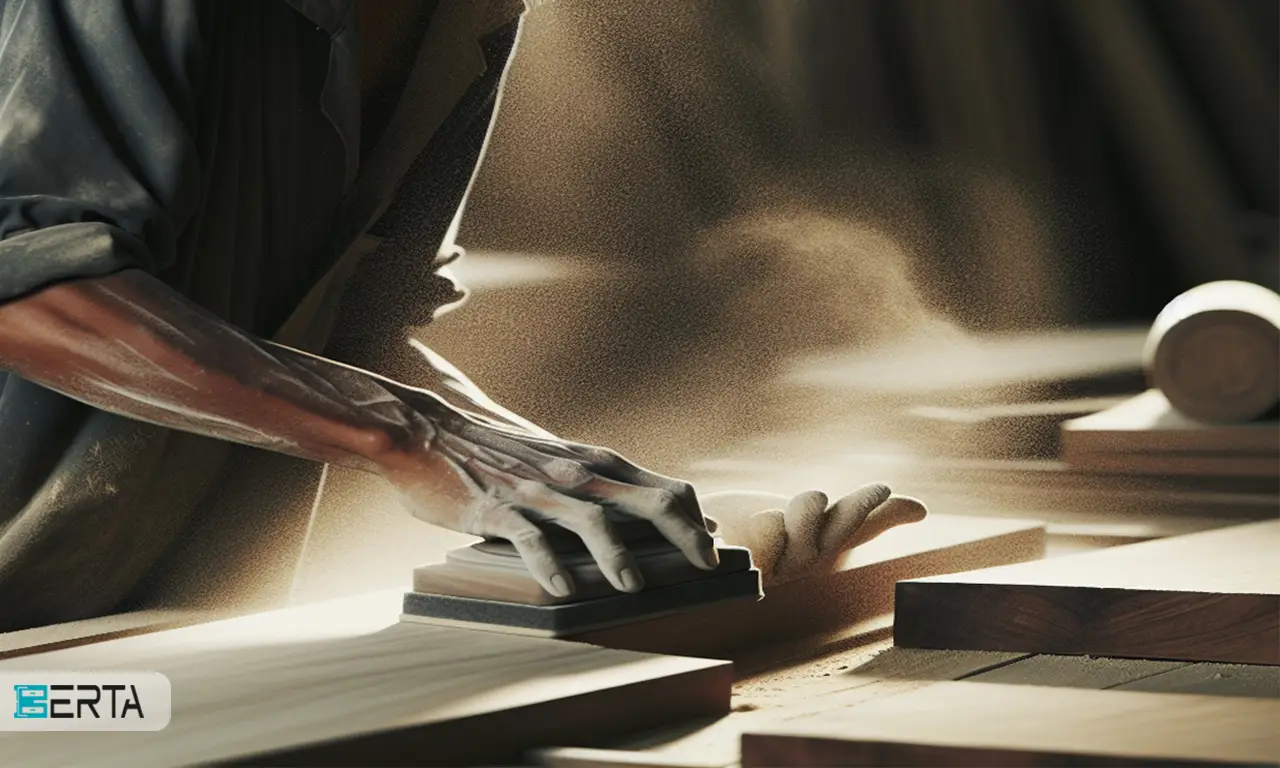

4- PVC sheet sandpaper

Smoother and polisher

The cut foam parts are smoothed and polished using sandpaper so that the appearance of the cabinet is beautiful and professional. This makes the surface of the cabinets ready for painting and the paint adheres well to the surface.

5- Assembly of cut parts

Initial assembly

The cut parts are assembled according to the original plan. This step includes connecting the parts using glue and screws. First, the main frame of the vanity cabinet is made, and then shelves and other components are added to it.

Vanity cabinet frame lining

Primer is placed on the cabinet frame to prepare the surface for painting. The primer makes the paint adhere well to the surface and creates a uniform coating.

6- Painting the vanity cabinet in the paint room

The vanity cabinets are completely painted in the room. This step involves applying several layers of paint to create a uniform and durable coating. Painting is done in a controlled paint room to avoid any contamination and dust.

7- Hinge and door installation

At this stage, hinges and doors are installed. Make sure they are aligned and working properly. Accurate installation of hinges and doors makes the vanity cabinets open and close easily and last longer.

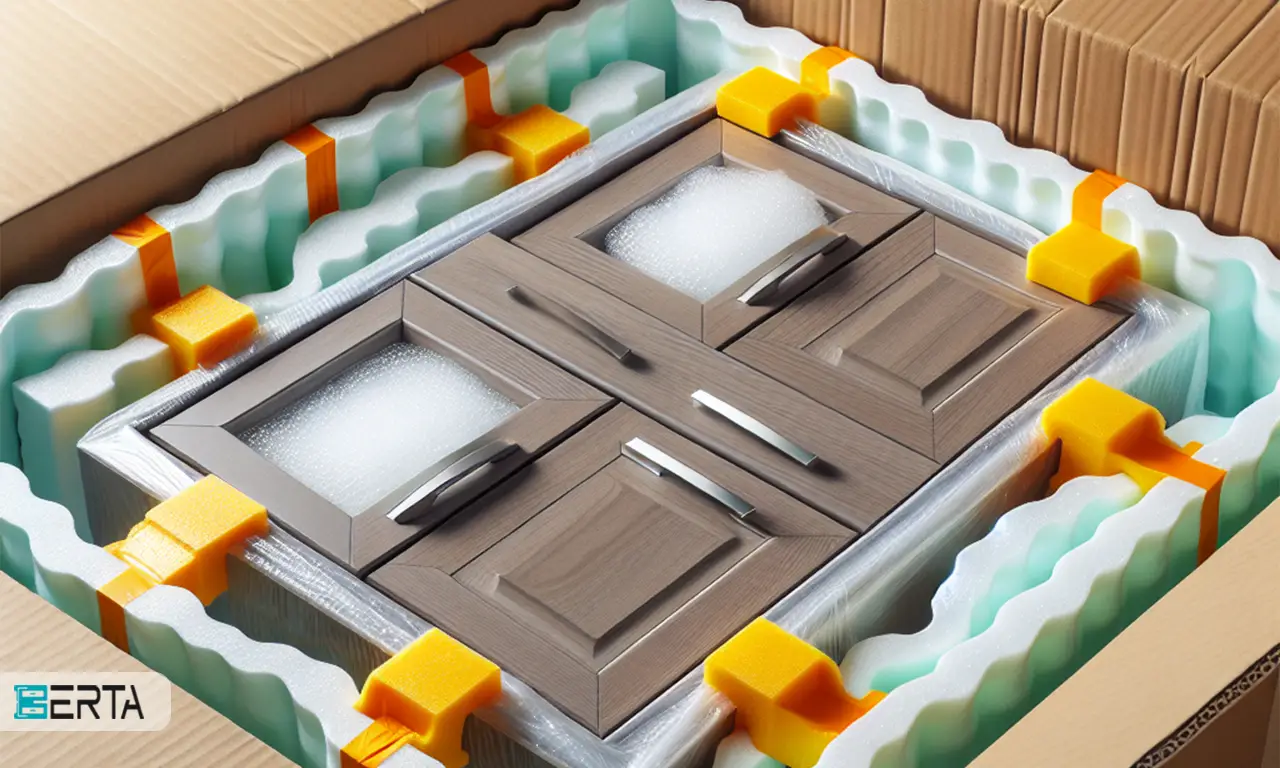

8- Final packaging

Finally, the vanity cabinets are packed so that they are not damaged during transportation and reach the customer. The packaging includes the use of resistant foams and cartons that protect the vanity cabinet from impact and scratches.

Buy a PVC vanity cabinet.

If you are looking for a vanity cabinet that is both beautiful and durable, PVC vanity cabinets are an ideal option for you. With its unique features, this vanity has attracted the attention of many people and has become one of the most popular choices in the market. To view the list of products, including PVC, wooden, and a combination of wood and PV vanity cabinets. To see different styles from classic and modern to minimal, visit Berta's website. Also, contact sales experts for more advice and to know about purchase conditions and special sales plans.

Comparison of vanity cabinet (PVC) with (MDF)

| Criterion | MDF vanity cabinet | PVC vanity cabinet |

| Weight | more weight | less weight |

| Moisture resistance | Less resistance | Much higher resistance |

| Heat resistance | Less resistance | More resistance |

| Resistance to insects | It may become problematic over time | More resistance |

| Beauty and diversity | More variety in design and color | Less variety in design and color |

| Price | lower price | higher price |

PVC vanity cabinet price

If you are looking to buy a PVC vanity cabinet, you should know that until the end of the construction process, the exact price of these vanities will not be fully determined. Several factors are influential in determining the final price of the PVC vanity cabinet. But if you are looking for high-quality and first-class vanity cabinets for your bathroom, spending a little more can give you a favorable and long-lasting result.

Why is the price of PVC vanity cabinets variable?

1- Raw materials and materials: the quality and type of PVC sheets used can have a great impact on the final price.

2- Design and customization: special designs and customization of the wardrobe can increase costs.

3- Construction and installation stages: different stages of construction and installation, from cutting and assembly to painting and final installation, all affect the price.

4- Fittings: Choosing high-quality and durable fittings can also lead to an increase in price.

Buy and price of PVC vanity cabinet

"Berta cabin" website offers all kinds of bathroom vanities with the best materials and the lowest prices among similar markets to you, dear customers. We are committed to providing quality and durable vanity cabinets that best meet your needs.

Why "Berta Cabin"?

1- High variety: all kinds of PVC, wooden, and mixed vanities in different styles from classic to modern.

2- Reasonable price: offering the best prices among similar markets.

3- Free consultation: Our team of consultants is ready to help you choose the best wardrobe.

4- After-sales service: Quality assurance and after-sales service for your peace of mind.

Conclusion

The process of making and buying a PVC vanity cabinet is a precise process that brings a beautiful and durable result. From the selection of high-quality raw materials to precise cutting and artistic assembly, each step requires attention and precision. After completing the cover and final connections, a beautiful and durable cabinet is prepared. When buying, it is important to pay attention to the quality of construction, unique design, and reasonable price. By following these tips, you can choose a vanity that doubles the beauty of your bathroom space and has high efficiency.

17938.jpg)

Whatsapp

Whatsapp  Telegram

Telegram