CNC (Computer Numerical Control) machines are known as one of the most advanced and efficient industrial machines. Using modern technologies, these machines can perform cutting, engraving, and shaping operations on various materials with very high precision. Here we will examine the performance, applications, types, and important points in choosing a CNC machine in more detail.

CNC machine performance

CNC machines are controlled using G-code and M-code codes. These codes teach the machine how and at what speed it should operate. The steps of the CNC machine are as follows:

- Model design: First, a three-dimensional model of the desired part is created using CAD (computer-aided design) software.

- Conversion to CNC code: The designed model is converted to G-Code and M-Code codes, which include commands related to movement, speed, and type of operation.

- Load code: The generated code is loaded into the CNC machine.

- Operation: The CNC machine automatically performs cutting, engraving, or shaping operations.

CNC machine applications

CNC machines are used in various industries and have various applications:

Woodworking industries

- Furniture production: Cutting and engraving on wood for furniture and interior decoration.

- Door and window production: Making wooden doors and windows with high precision.

- Artistic engraving: Creating artistic and decorative designs on wood.

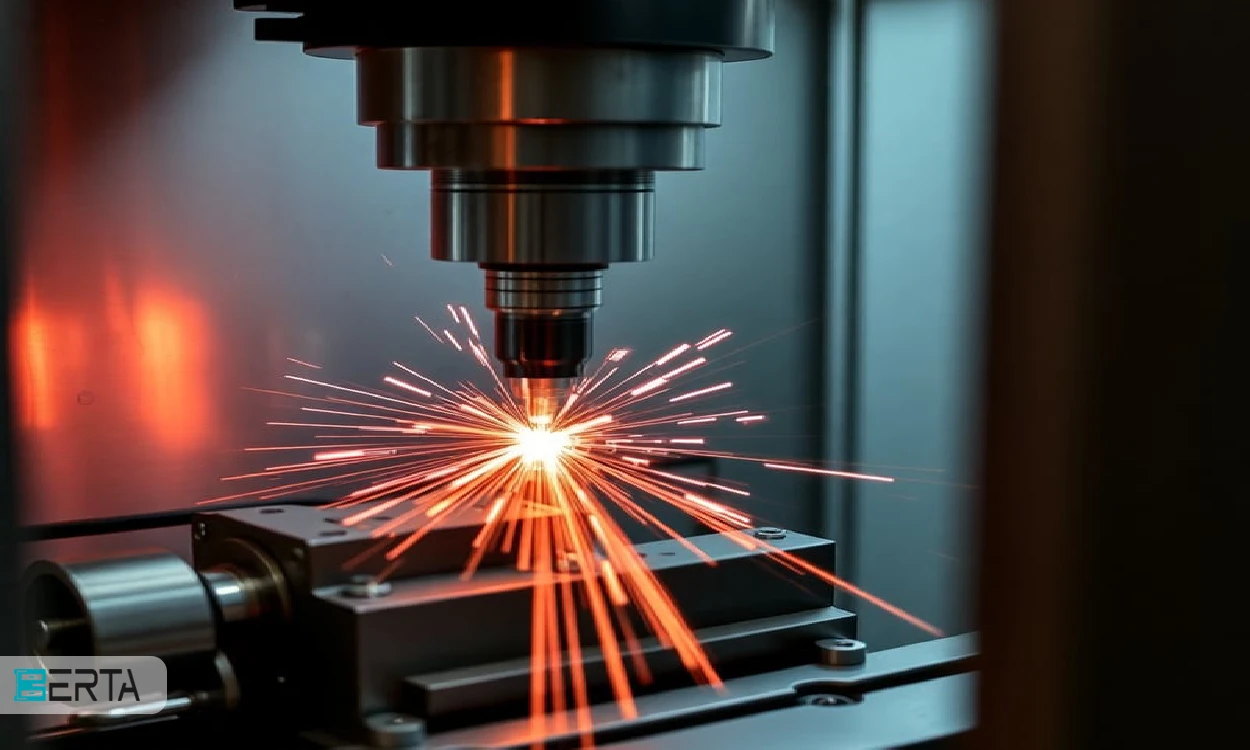

Metal industry

- Machining: Producing precise metal parts for machinery and equipment.

- Laser cutting: Cutting metal sheets with high precision and speed.

- Molding: Producing metal molds for various industries.

Plastic industry

- Cutting and shaping: Cutting plastic into various shapes and producing plastic parts.

- Plastic engraving: Creating various designs on plastic products.

Electronic industry

- Electronic board drilling: Engraving and drilling for producing printed circuit boards (PCB).

- Electronic parts production: Producing precise parts for electronic devices.

Jewelry industry

- Jewelry engraving: Creating beautiful and precise designs on gold and jewelry.

- Gold mold production: Making precise molds for gold casting.

Types of CNC Machines

CNC machines are divided into several categories, each with its characteristics and applications:

1- CNC Lathe

CNC lathes are designed to turn circular and cylindrical parts. These machines can cut various materials, including metals and plastics, with high precision. These machines usually have a main axis on which the workpiece is placed and the cutting tool rotates around it.

Example: CNC lathes are used to produce engine shafts, which require high precision and a smooth surface. These machines can produce shafts with an accuracy of a few microns.

2- CNC Milling Machines

CNC milling machines are designed to cut and shape materials using rotating cutting tools. These machines usually have multiple axes of motion, which allows them to create more complex shapes.

Example: In the automotive industry, CNC milling machines are used to produce parts such as cylinder heads and engine bodies. These parts require high precision and a smooth surface, which can be achieved using CNC milling.

3- CNC drilling machines

CNC drilling machines are designed for deep and precise drilling. These machines are usually used to produce large and heavy parts and can create holes of different diameters and depths.

Example: In the construction industry, CNC machines are used to produce large parts such as beams and columns. These machines can create precise holes for installing fittings and accessories.

4- CNC cutting machines

CNC cutting machines come in different types that are used to cut different materials using different technologies such as laser, plasma, and waterjet. These machines are popular in various industries due to their high precision and speed.

Example:

1- Laser cutting: Laser cutting is used to cut metal sheets of different thicknesses, such as in the production of advertising signs and automotive parts. This method is very popular due to its high precision and lack of post-cutting operations.

2- Plasma cutting: Plasma cutting is used to cut thick metal sheets, such as in the production of metal structures. This method is used in heavy industries due to its high speed and low cost.

3- Waterjet cutting: Waterjet cutting is used to cut sensitive materials such as glass and ceramics. This method prevents material deformation due to the lack of heat generation.

5- CNC punching machines

CNC punching machines are used to punch holes in metal sheets and produce parts with special shapes. These machines usually have an automatic tool change system and can make multiple holes quickly and with high accuracy.

Example: In the electronics manufacturing industry, CNC punching machines are used to produce printed circuit boards (PCBs) and metal parts. These machines can make precise holes for installing electronic components.

6- CNC engraving machines

CNC engraving machines are used to create designs and writing on various surfaces. These machines usually have special tools that can be engraved with high accuracy.

Example: In the jewelry industry, CNC engraving machines are used to engrave names or special designs on jewelry. These machines can create very fine details with high precision.

Important points in choosing a CNC machine

When purchasing a CNC machine, it is important to pay attention to the following points:

- Spindle power and speed: The power and speed of the spindle have a great impact on cutting quality and production speed.

- Machine accuracy: The accuracy of the CNC machine must be in line with industrial needs. High accuracy helps produce quality parts.

- Number of axes of the machine: The more axes of the machine, the more freedom you will have to create complex shapes. 5-axis machines are usually used to produce more complex shapes.

- Body material and parts: The quality of the machine's construction affects its lifespan and efficiency. Machines with a solid body and high-quality parts usually have a longer lifespan.

- Warranty and after-sales service: It is of great importance and should be paid attention to. Proper after-sales service can help when repairs and maintenance are needed.

Conclusion

CNC machines have revolutionized various industries by providing high accuracy and speed and are known as efficient tools for cutting and engraving various materials. Depending on the specific needs of each industry, choosing the right machine can have a significant impact on increasing productivity and reducing costs. As technology advances, CNC machines are expected to become more advanced and efficient day by day, playing an increasing role in various industries.

17938.jpg)

Whatsapp

Whatsapp  Telegram

Telegram